As a logistics manager, you may have engaged with route optimization solutions: you use fleet tracking systems, delivering orders, and reduced the number of vehicles and the traveled distance.

However, if your supply chain metrics are still weak, and your customer service indicators still show a problem on the road, can you make critical decisions with them at the right time?

Today, the integration of information technology(IT) in the supply chain and logistics industry is not only a reality but a must-have.

What does actionable mean?

“Actionable” is a term coined in the defense industry and increasingly used in business. According to the Collins Dictionary, actionable intelligence is “the necessary background information that will enable someone to deal quickly and efficiently with a particular situation”.

Leaders in the logistics and supply chain industry have gone past just revising data. According to the Aberdeen Group Report-Fleet Management Trends: Mobile Assets Move Beyond the Map, we are past the classic top reasons to track vehicle information: to review location, vehicle speed and idle time. Today, it is increasingly important to improve the quality of performance, checking out your drivers, vehicles and customers.

The top pressure driving firms to connect to assets and resources in real time is the need to improve productivity and efficiency of the fleet. Vehicle insight can lead to improved resolution and performance.

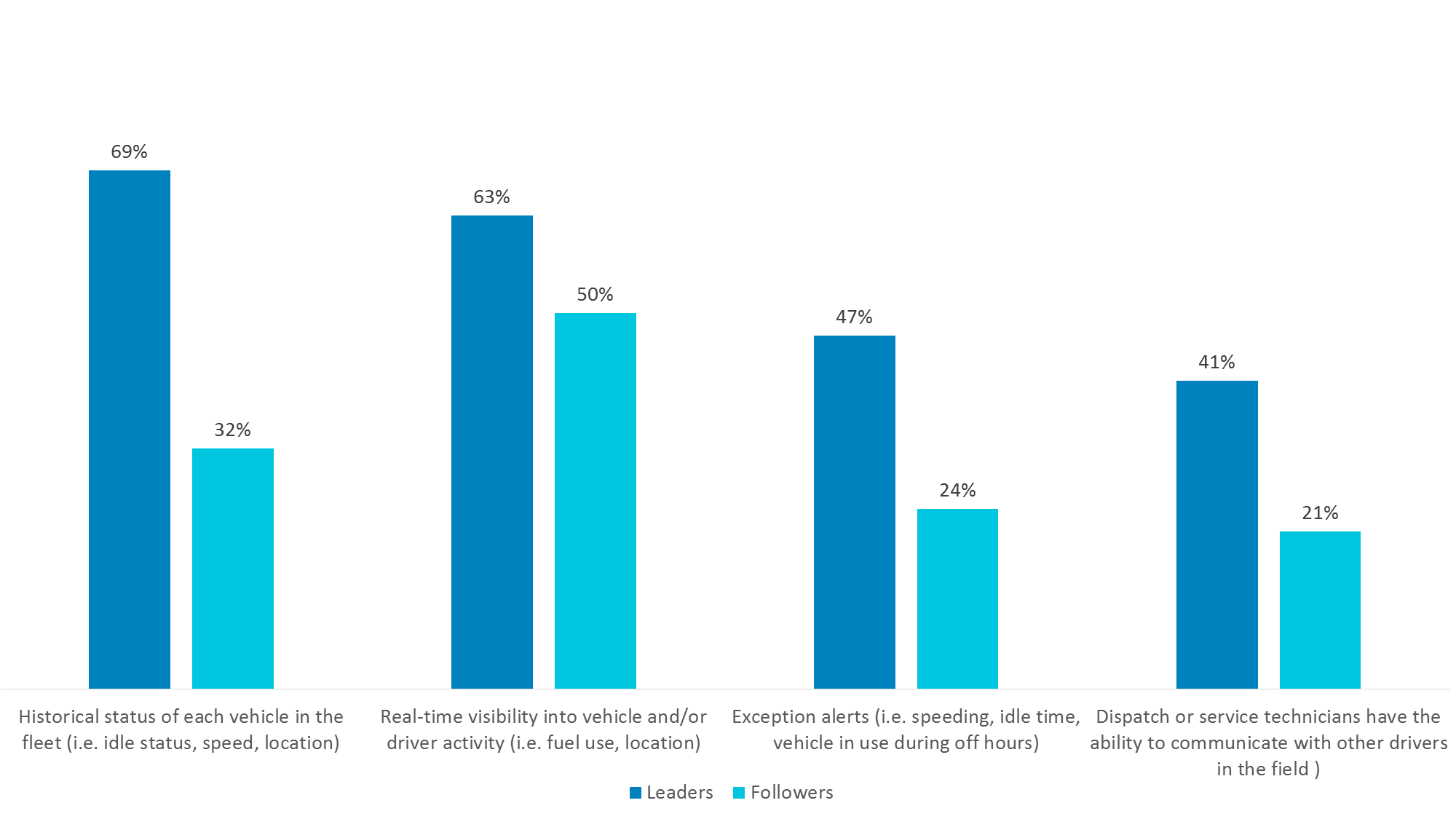

According to the report, leading managers have more trends to analyze:

- The historical status of each vehicle in the fleet

- Real-time supply chain visibility into vehicle or driver activity

- Exception alerts

- Dispatch or service technicians who have the ability to communicate with drivers in the field.

Source: Aberdeen Group Report-Fleet Management Trends: Mobile Assets Move Beyond the Map

| Top strategies in fleet management | Leaders | Followers |

| Capture performance data in real-time and integrate with back-end customer management or enterprise systems | 67% | 55% |

| Provide service business leaders with on-demand access to performance information | 56% | 36% |

| Provide customers with increased visibility | 39% | 34% |

Source: Aberdeen Group Report-Fleet Management Trends:

Mobile Assets Move Beyond the Map

1. How’s my driver doing?

According to the Aberdeen group, a cost of a poor driver behavior “not only results in a damaged vehicle but could also lead to a technician who may be delayed or unable to make an appointment due to an accident or traffic violation”.

2. My data reported issues last month. How can I do something about it now?

One of the biggest problems with the traditional use of a route optimizer is that, by the time decision makers get to revise data, it becomes too late to make preemptive reactions.

3. My routes are not working according to plan. Why?

Nobody gets it right at first. However, many companies fail to grasp the value of an “on-the-route learning” with fleet management systems, because decision makers are kept out of the loop from on-the-route issues. Perhaps a delivery or shipment was sent on time, but the driver or vehicle faced problems on the road whose resolution was taken for granted. If your computer works out an optimal route, but most people took an alternative, you have a problem.

4. I’m feeling lost in translation.

You may be getting weekly reports with a simple, easy-to-read stats and indicators carefully adapted from the dashboard. Many times there are issues left out of the executive summary because the person in charge of simplifying the final report did not think it was critical in the first place. Then, your team spends countless hours trying to find the information gap that could’ve been easier to spot if the original dashboard had been simpler in the first place.

Do you still feel left out in route planning?

Drivin will address customers at the 2016 Logistec Expo in Santiago on 19th - 20th May. We will take customer's questions and make real-time demonstrations of our route optimization software, real-time monitoring, and issue based alerts and alarms, so they can revise for themselves how these tools can improve supply chain management processes.

.jpg)

.jpg)